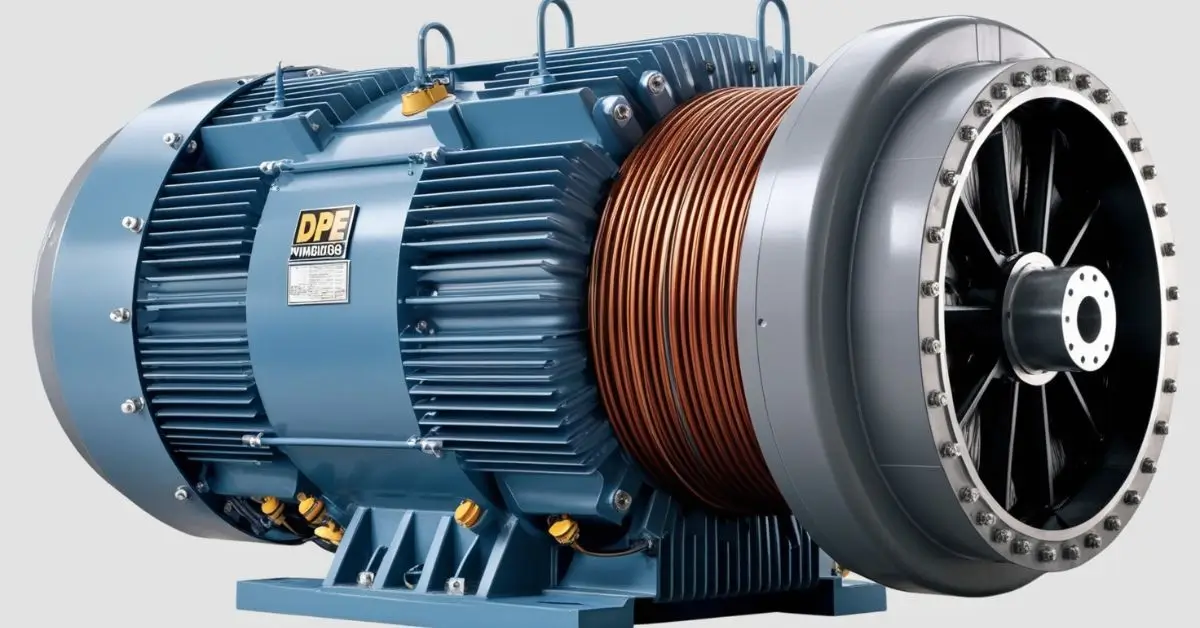

DPE windings, or Direct-Phase Excitation windings, are crucial components in many electrical systems, particularly in generators. They play a significant role in ensuring reliable voltage regulation and stability, which is essential for the efficient operation of power generation systems. In this comprehensive guide, we will explore what DPE windings are, how they work, their applications, maintenance tips, advantages, challenges, and much more.

Understanding DPE Windings

DPE windings are a type of excitation winding used in generators, specifically designed to provide the necessary excitation current for the rotor of a generator. The excitation system controls the field current, which is essential for maintaining the generator’s voltage output. The role of the DPE windings is to provide self-excitation, which means the windings generate the necessary voltage without relying on external power sources.

These windings are typically part of the generator’s stator, and they work in conjunction with the Automatic Voltage Regulator (AVR) to ensure the generator produces a stable and reliable voltage output, even under varying load conditions. DPE windings use the residual magnetism in the rotor to generate the initial excitation current. This current is then regulated by the AVR to maintain consistent voltage levels as the generator operates.

How DPE Windings Work

The fundamental operation of DPE windings revolves around the process of self-excitation. When the generator starts running, the residual magnetism in the rotor generates a small initial voltage in the DPE windings. This initial voltage is sent to the AVR, which further regulates the current to ensure that the excitation current stays within the required limits.

The AVR adjusts the current supplied to the DPE windings based on the load demand. If the load increases, the AVR increases the excitation current to maintain the output voltage. Conversely, when the load decreases, the AVR reduces the excitation current. This regulation ensures that the generator produces a consistent voltage output, even as the load fluctuates.

DPE windings are typically part of the stator, but the rotor also plays a role in the excitation process. The rotor’s magnetic field interacts with the stator windings to produce the electrical current required for excitation. This system is a form of electromagnetic induction, where the movement of the rotor’s magnetic field induces a current in the stator windings.

Applications of DPE Windings

DPE windings are commonly used in a variety of power generation applications, including both industrial and portable generators. Below are some key areas where DPE windings are applied:

- Industrial Generators: DPE windings are frequently found in industrial generators, where reliability and consistent performance are critical. These generators power manufacturing plants, data centers, and other large-scale facilities that require a stable power supply.

- Portable Generators: Many portable generators use DPE windings due to their ability to self-excite, eliminating the need for external excitation sources. This feature is particularly useful in mobile or temporary power setups, where space and complexity need to be minimized.

- Backup Power Systems: In emergency backup power systems, DPE windings ensure that the generator can start quickly and provide a stable voltage output without relying on external power sources.

- Renewable Energy Systems: Some renewable energy systems, such as wind and hydroelectric generators, also use DPE windings as part of their excitation system to maintain consistent voltage output under varying environmental conditions.

Comparison with Other Excitation Systems

While DPE windings provide several benefits, they are not the only type of excitation system used in generators. Below, we compare DPE windings with other common excitation systems to highlight their unique features.

| Feature | DPE Windings | Permanent Magnet Generator (PMG) | Shunt Excitation |

|---|---|---|---|

| Self-Excitation | Yes | No | Yes |

| Voltage Stability | High | Very High | Moderate |

| Response to Load Changes | Quick | Immediate | Delayed |

| Cost | Moderate | High | Low |

- PMG (Permanent Magnet Generator): This system uses permanent magnets instead of residual magnetism to generate the excitation current. It is highly stable and provides excellent voltage regulation. However, it is typically more expensive than DPE windings and is not as widely used in all generator types.

- Shunt Excitation: In this system, the excitation current is provided by a separate power source. It is generally more cost-effective but may not be as responsive to rapid load changes. Additionally, the performance of shunt excitation systems can degrade when powering non-linear loads due to harmonics.

Maintenance and Troubleshooting of DPE Windings

While DPE windings are reliable, they still require regular maintenance and attention to ensure optimal performance. Below are some key maintenance tips for ensuring your DPE windings remain in good condition:

1. Regular Inspection

Inspect the DPE windings periodically to check for signs of wear, corrosion, or physical damage. This can include looking for any cracks or degradation in the insulation that may indicate a short circuit or other issues.

2. Check for Short Circuits

Using a multimeter, you can check for short circuits in the windings. If the windings are shorted to ground, they will need to be replaced immediately to avoid further damage to the generator.

3. Monitor the Residual Magnetism

The rotor’s residual magnetism is essential for generating the initial excitation current. Over time, this magnetism can decrease, which could lead to poor voltage regulation. If the residual magnetism is too low, it may be necessary to “flash” the generator to restore it.

4. Perform Insulation Resistance Tests

Insulation resistance tests help identify any potential breakdowns in the insulation of the windings. If the resistance readings are too low, the windings may need to be replaced.

5. Clean the Windings

Dirt and debris can accumulate on the windings over time, leading to reduced efficiency and potential overheating. Regular cleaning helps maintain optimal performance.

6. Check AVR Functionality

Since DPE windings rely heavily on the AVR for voltage regulation, it is important to ensure that the AVR is functioning correctly. An improperly calibrated AVR can cause instability in the voltage output, affecting the overall performance of the generator.

Advantages of DPE Windings

There are several advantages to using DPE windings in generator systems:

- Self-Excitation: DPE windings do not require an external excitation source, making them more convenient and reliable.

- Cost-Effective: Compared to other excitation systems, DPE windings are relatively affordable, especially when considering their performance benefits.

- High Voltage Stability: DPE windings provide stable voltage regulation, ensuring consistent power output.

- Quick Response to Load Changes: The excitation current is adjusted quickly in response to load variations, preventing voltage dips or spikes.

Challenges with DPE Windings

Despite their many advantages, there are some challenges associated with DPE windings:

- Load Dependency: DPE windings are more sensitive to load changes than some other excitation systems. Rapid load fluctuations can lead to slight voltage instability, although the AVR usually compensates for this.

- Complex Maintenance: While DPE windings are relatively low-maintenance, when issues do arise, diagnosing and fixing them can be more complicated than other simpler excitation systems.

- Vulnerability to Harmonics: Non-linear loads can introduce harmonics into the system, which may affect the performance of DPE windings and the AVR.

Conclusion

DPE windings play a critical role in maintaining the performance and reliability of generators. By providing self-excitation, they eliminate the need for external power sources, making them ideal for portable and industrial applications. They offer several benefits, including high voltage stability and quick responses to load changes, but they also come with challenges, such as sensitivity to harmonics and load dependency.

Proper maintenance and monitoring of DPE windings are crucial to ensuring their longevity and optimal performance. Regular inspection, checking for short circuits, and performing insulation resistance tests are key to keeping these windings in top condition.

As the demand for reliable power generation systems continues to grow, understanding the importance of DPE windings and their role in excitation systems will be essential for operators and technicians alike.